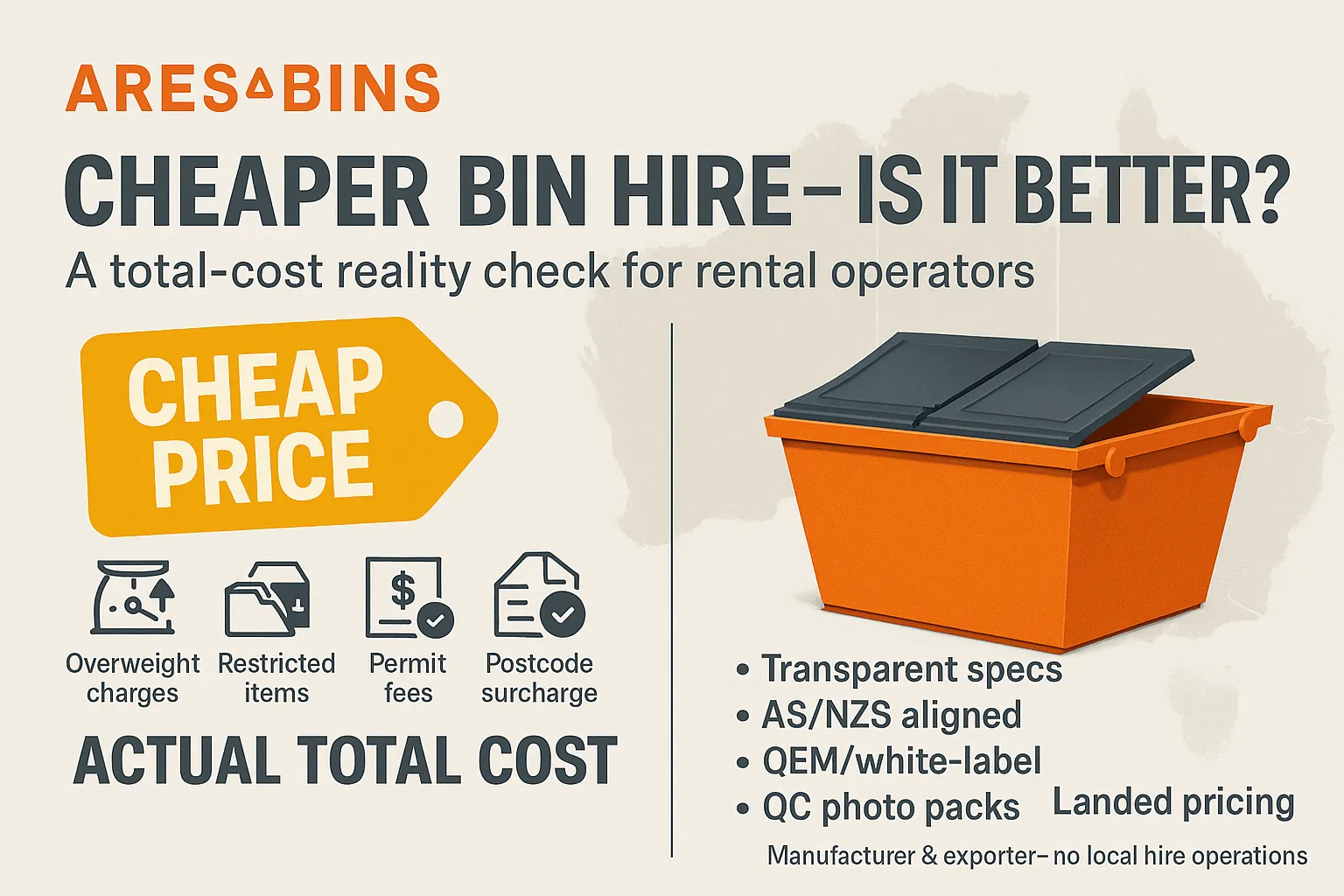

A total-cost reality check for rental operators and local manufacturers

A “cheap daily rate” rarely equals the lowest total cost of ownership (TCO). In day-to-day operations, many “low-price offers” quietly shift costs into overweight charges, restricted items, extended hire, failed access, postcode surcharges, and other fine print. Over longer relationships, beware of teaser rates + automatic price escalators + minimum tonnage + auto-renewal clauses—attractive up front, erosive over the contract term.

Where Aresbins fits: we are based in China and focus on manufacturing and exporting skip bins (Mini/Midi/Hooklift) for Australian rental companies and local manufacturers (OEM/white-label). We do not provide hire or operations overseas. Working with many partners has made one truth clear: “cheap” is not the finish line—predictability and transparency are.

1) Why “low entry price” often ends as “high final bill”

-

Weight & loading: Advertised prices usually include only a baseline weight/capacity. Exceed it and stepped overweight charges apply. Overfill above the rim or poor loading can trigger extra fees and disputes.

-

Waste categories & processing: Mattresses, plasterboard, bricks/concrete, tyres, whitegoods, and green waste are often surcharged or restricted—easy to miss at booking, expensive at settlement.

-

Hire window & changes: Over-hire days, re-scheduling, no-access calls, night/weekend collections—all create re-dispatch and dead-mileage you pay for somewhere.

-

Area & delivery: Postcode surcharges, second trips, remote-zone fees can be buried beneath an attractive headline rate.

-

Long-term clauses: A low starter price linked to annual indexation/minimum tonnage/auto-renewal steadily pushes up the average cost over time.

Bottom line: If a quote is made “cheap” by omission, the final invoice will recover those omitted costs—plus time lost in customer service, driver hours, yard turnaround, and brand goodwill.

2) Kill hidden costs at the source—with better containers

Aresbins does one thing: engineer and build the container right, so your site runs smoother with fewer disputes—making your public terms clearer and more enforceable.

-

Cleaner discharge, faster turnaround: Smooth interiors and tight radii reduce hang-ups and residue; tipping is more complete, cycles are quicker.

-

Avoid “rain weight” surprises: Solid/mesh/lockable lids limit water ingress and windblown litter, reducing overweight disputes caused by saturation.

-

Less breakage & contamination: Drop-front doors let heavy items roll in instead of being thrown, preventing fragmentation and mixed loads.

-

Separation at the point of loading: Colour-coding and on-bin labels (Mixed / Recyclables / Green) cut contamination rates and downstream add-on processing fees.

-

Yard & backhaul efficiency: Standardised footprints and lift points fit mixed fleets; stackable/nestable designs increase yard density and reduce empty-run costs.

-

Longer life & stronger residual value: Plate thickness and beam reinforcement, abrasive blasting + epoxy/PU systems (hot-dip galvanising optional) slow corrosion and fatigue, cutting repairs and downtime.

When the “usual pain points” are solved in hardware, your terms can be transparent, your teams spend less time firefighting, and complaints naturally decline.

3) Long-term “anti-surprise” checklist

-

Price basis: Is the rate landed/door-to-door, GST-inclusive, incl. delivery & pickup? If not, list each component.

-

Weight & evidence: Included allowance; overweight charged per 100 kg or per tonne; will weighbridge evidence be provided?

-

Loading rules: No overfill above the rim; if it happens, fixed fee per incident with driver authority on site.

-

Restricted/surcharged items: Mattresses, tyres, whitegoods, plasterboard, bricks, soil, green waste—list unit prices or prohibition.

-

Hire window & exceptions: Standard days, over-hire (per day), failed access (per visit), re-schedule, night/weekend call-outs.

-

Permits: If placed on public land, who obtains and who pays for permits.

-

Safety & compliance: Reflectives, load lines, hazardous “no-go” lists printed on the bin.

-

Contract mechanics: Frequency/basis for price adjustments, minimum tonnage or hire levels, auto-renewal and termination terms.

4) What Aresbins supplies

-

Manufacture & export: Built in China and exported overseas; we do not sell to end consumers or operate local hire services.

-

OEM/white-label: Paint colours, logos, numbering, and asset labels matched to your system for a unified fleet look.

-

Process & repeatability: CNC/laser cutting, precision fit-up, robotic welding; abrasive blasting + epoxy/PU coatings; hot-dip galvanising optional.

-

Specs & options: Mini/Midi 2–6 m³, Hooklift 10–30 m³; drop-front doors, reinforced floors, lockable/mesh lids, drain points, colour streams and label kits.

-

Quality & documentation: AS/NZS-aligned drawings and markings; batch QC photo packs and dimensional checks supplied for receiving and audit.

-

Packaging & logistics: Sea-freight-friendly reinforced packaging and tie-downs; commercial terms EXW/FOB/CIF/DDP as agreed.

Our aim is straightforward: help you achieve faster turns, fewer after-sales issues, and clearer customer terms—so the “cheap illusion” gives way to a controlled total cost.

5) Procurement & replenishment tips

-

Standardise first (footprints, lift points, door types, plate gauges) to cut cross-fleet adaptation time.

-

In rainy or coastal regions, prioritise lids and corrosion systems (galvanising or high-build coatings).

-

For heavy-material customers, specify reinforced floors/beams and drop-front doors to reduce damage and downtime.

-

Deploy colour/label stream kits for common scenarios (Mixed / Recyclables / Green) to lower contamination and disputes.

-

Request QC photo packs and dimensional records with every batch to keep mixed inventory traceable.

Closing & next steps

A cheaper daily rate isn’t always cheaper overall; transparent terms and reliable equipment are.

If you’re an Australian skip-hire operator or local manufacturer, ask Aresbins for:

-

Specs & options for Mini/Midi/Hooklift,

-

Sample/pilot-run workflow with a QC photo pack example,

-

EXW/FOB/CIF/DDP comparative quotations (with landed-cost breakdown if required).

Aresbins (China)—focused on manufacturing and export, using explainable configurations and consistent production to turn price into performance.

Recent Comments