ARESBINS

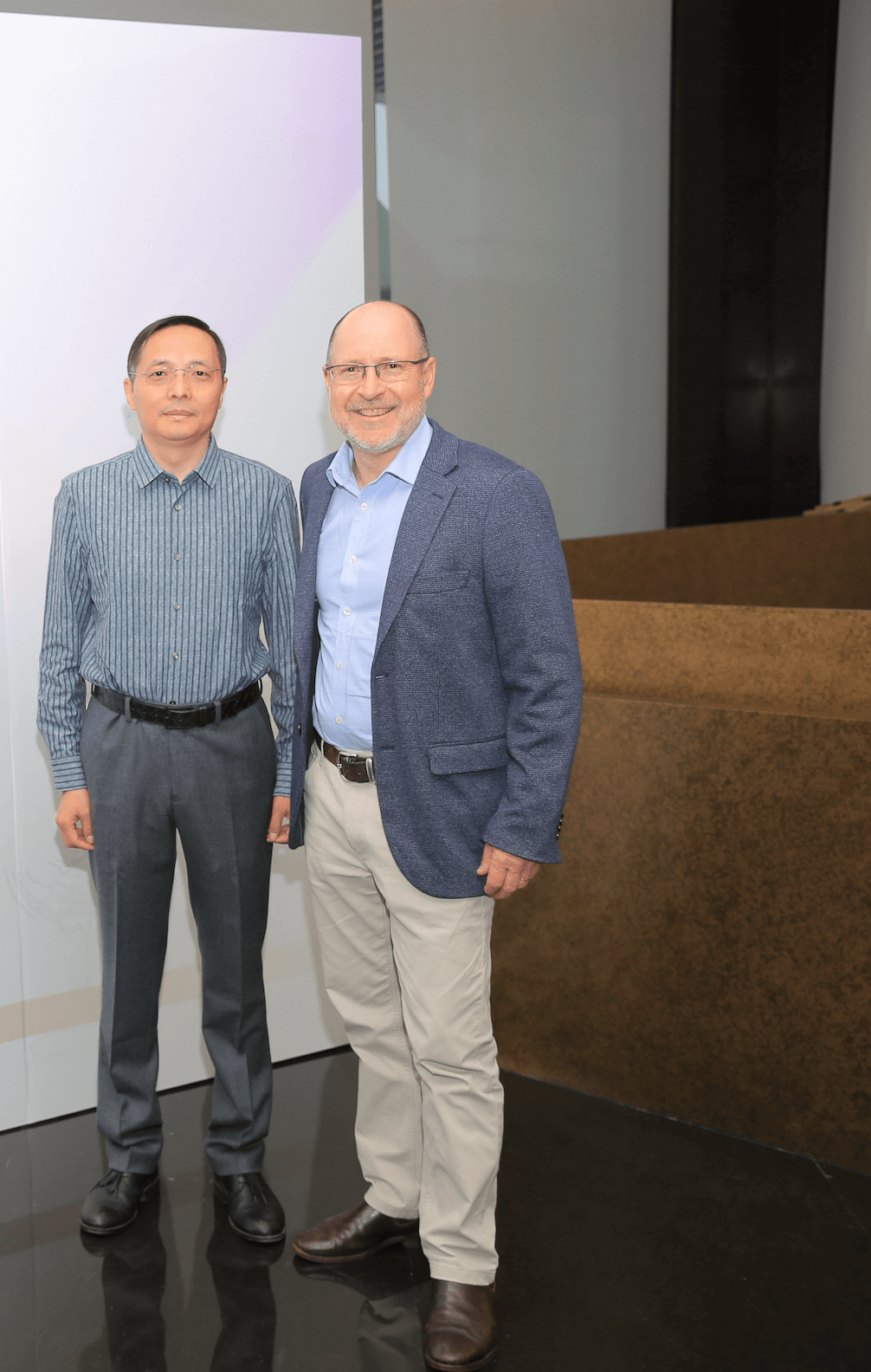

John Hu

FOUNDER

-

Aresbins Founder — John Hu

John Hu could be considered one of the last passengers aboard China’s golden age of foreign trade. Over more than a decade of dealing with quotes, sample boxes, and shipping schedules, he came to understand a simple yet crucial truth: what customers truly want is never vague adjectives like “high-quality” or “durable”—but rather precision and predictability, down to the smallest detail.

In 2004, riding the wave of booming foreign trade, he left a stable position at a coastal trading company and returned to Anlu, Hubei with several former colleagues to establish a new factory specializing in tires and other rubber products for small Australian trash bins. In the beginning, they set up a production line in a dusty old workshop. These seemingly insignificant rubber parts—monotonous as the work may have been—acted like a whetstone, honing the team’s ability to accurately translate drawings into physical products and their risk control awareness to curb minor errors before they escalated into major costs. Those late nights spent repeatedly adjusting molds and early mornings re-testing over mere grams of deviation became the foundation upon which the factory was built.

A turning point in their fate arrived quietly in the form of a referral letter from Australia. The order was more than ten times larger than any they had handled before, yet the buyer’s requirements were straightforward and stringent: technical drawings compliant with AS/NZS standards, a delivery window with no more than three days of variance, and authentic quality data attached with inspection IDs. Instead of rushing to accept the order, John first restructured the business framework: precision-demanding tasks like engineering design, sample testing, and client communication were stationed in Wuhan to leverage talent and information advantages, while the Anlu workshop, deep within the supply chain, focused on straight-through production. The former ensured “making promises accurately,” and the latter guaranteed “delivering on those promises.” This clear division of labor provided a solid structural support for their commitment to “walking the talk.”

The real challenges, however, always lay in the details. On one occasion, a shipment encountered issues in maritime transport due to discrepancies between the declared weight and the actual weight. John immediately had floor scales installed overnight and mandated that every shipment must leave the factory with weighing slips and multi-angle photos—making “weight verification” the 17th step in the production process. When coastal clients reported that the container coating was prone to wear in humid and hot environments, he promptly introduced sandblasting rust removal pretreatment and upgraded from ordinary paint to an epoxy-polyurethane composite coating. Every problem was met not with an apology but with a new rule: “This is how it must be done.”

By the time their brand Aresbins fully entered the Australian market for dump hooks and skip bins, the company had long escaped the mire of “competing on low prices” and instead forged “transparency” into its core competitiveness. Sales staff brought testing tools to onsite quotes; clients could monitor production progress in real time; 24 hours before shipment, the quality control team would take detailed photos with serial numbers, annotating everything from weld smoothness to coating thickness. Even in mass production, the dimensional error between the 100th unit and the 1st was strictly controlled within 2 millimeters. In 2020, the company invested heavily in robotic welding arms, CNC cutting systems, and standardized jigs—not to “show off” to customers, but to achieve that simple and steadfast goal: making the 1000th unit look exactly like the 1st.

At its peak, the lights in two workshops burned through the night, with over 200 workers operating in shifts. Their clients included international rental giants expanding their fleets and large manufacturers using Aresbins as a white-label supplier—what they sought was never “surprise,” but “peace of mind.” When asked about the secret to this model, John Hu calmly pointed to the slogan on the workshop wall: “Safety First, Production Second.” To him, “safety” was not just an operational guideline but a form of profound respect: providing workers with clear and stable procedures, and giving customers reliable quality expectations. Even a seemingly minor promise like “samples will be shipped by 10 AM tomorrow” was worth going all out to keep.

His products were not complicated—just steel-welded bins and load-bearing frames. But turning “simple products” into “remarkable certainty” relied on an interlocking, self-improving operational system. In the turbulent waters of foreign trade, compared to chasing exchange rate fluctuations or hopping on trendy products, this kind of persistence—“welding promises into the process”—may be the most solid vessel for breaking through the waves.

Built Tough, Built for You: The Ultimate Skip Bin Solutions for Australia

Uncompromising Strength Meets Custom Innovation In the demanding Australian waste management and construction sectors, standard off-the-shelf bins simply don't cut it. Your equipment faces extreme daily abuse—from heavy concrete and demolition waste to corrosive...

Stepping into 2026: Fully Powered to Support Australia’s Growing Waste Management Needs

Welcome Back to a Massive Year Ahead! As the Lunar New Year celebrations come to a close, the entire team at Aresbins is thrilled to be back on the factory floor. We have officially resumed full-scale production, completely recharged and ready to tackle what promises...

The “CNY Shutdown” Alert: Why Australian Skip Bin Fleets Must Order Now to Hit the EOFY Deadline

It is happening right now. As you read this (January 20th), the world’s largest manufacturing engine is winding down. The Lunar New Year is upon us, and for the next four weeks, global steel fabrication effectively hits the pause button. For waste management operators...