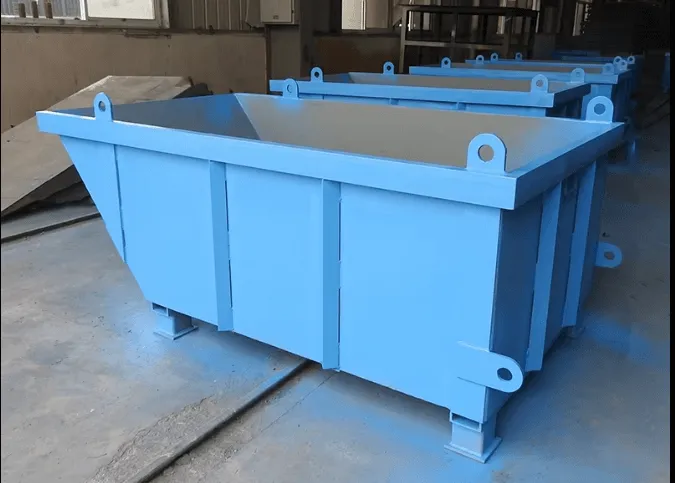

A crane skip bin, also called a craneable skip bin or hook craneable skip bin, is a special waste container designed for lifting and moving by overhead cranes or hydraulic arms. These bins are commonly used in large construction, industrial, and manufacturing sites where regular skip bins aren’t practical due to space or operational limitations.

Key Features of a Crane Skip Bin

- Tapered design for easier emptying

- Forklift pockets for simple handling

- Heavy-duty lifting and tipping points for durability

- Complies with local standards (e.g., Australian Standards)

- Comes with a crane certificate, operating procedures, and risk assessments for safety

Usage and Applications

- Used in construction, manufacturing, and mining operations

- Suitable for industries like construction, mining, manufacturing, defence, and shipping

Safety and Compliance

- Crane certified for safe operation

- Includes operating procedures and risk assessments for workplace safety

Customization and Durability

- Customizable to meet specific needs

-

Design Improvements:

- Lifting lugs were added, enabling crane use and expanding applications in industrial and construction projects.

- Tipping mechanisms simplified unloading, reducing manual effort and improving efficiency.

-

1960s Advancements:

- Larger vehicles with hydraulic arms were introduced, making skip bins easier to transport and unload.

- Specialized lorries and cranes became standard, streamlining delivery and collection processes.

-

Global Expansion:

- By the 1960s, skip bins reached Australia, where hire companies offered various sizes to meet diverse waste management needs.

-

Modern Features:

- Today’s skip bins include crane-compatible designs, online booking systems, and trucks with specialized loaders. These innovations have made waste management more convenient and efficient.

ARES Bins manufactured is at the forefront of modern waste management, offering skip bins designed to meet today’s demands.This evolution transformed simple metal containers into the versatile, indispensable tools used worldwide today.

Key Features of Crane Skip Bins

Crane skip bins are built for efficient and secure waste management, especially in construction and industrial environments. They offer several important features that improve their performance and flexibility.

Tapered Design

Crane skip bins have a tapered design, which makes it easier to unload materials like soil, sand, and rubble. This design ensures smooth and fast discharge of contents, improving efficiency.

Lifting Points

These bins have four heavy-duty lifting points for secure and stable lifting by cranes. These points are crucial for safely transporting heavy loads, reducing the risk of accidents during lifting.

Tipping Mechanisms

Crane skip bins include tipping mechanisms for easy unloading. Some models have a pivoting yoke that locks flatly into place at the rear of the bin. This allows the bin to hang vertically and empty its contents easily when lifted.

Fork Pockets and Crane Lugs

The bins are fitted with fork pockets for easy transport by forklifts and crane lugs for lifting by overhead cranes. This dual functionality adds convenience and versatility on job sites.

Compliance with Standards

Crane skip bins meet local compliance standards, such as Australian Standards. They come with the required certificates, operating procedures, and risk assessments to ensure safety and compliance at work.

Volume Capacities and Load Limits

Crane skip bins come in various volume capacities, including 0.8 m³, 1 m³, 1.5 m³, 2 m³, 3 m³, 4 m³, and 6 m³, so users can select the right size for their needs. The Working Load Limits (WLL) range from 3 tonnes to 14 tonnes, depending on the model, ensuring they can handle heavy loads effectively.

Material and Durability

Made fromQ235 steel.It is a low-carbon structural steel commonly used in China for various industrial applications. It is valued for its balance of strength and flexibility, making it useful for mechanical manufacturing and construction.For details, please refer to our previous blog

Environmental Considerations

Using crane skip bins in construction projects requires a focus on environmental sustainability through effective waste management and recycling. Here are some key considerations:

Waste Segregation and Recycling

Crane skip bins make waste segregation easier, which is crucial for recycling. Specific skips, such as concrete skips or general trash skips, help separate materials. For instance, concrete skips collect concrete mixes for recycling, reducing landfill waste and supporting sustainability.

Responsible Disposal

Proper material disposal minimizes environmental harm. Construction sites produce large amounts of waste, and using specialized skips for different materials ensures efficient management. This practice supports recycling and lowers the project’s environmental impact.

Site Rehabilitation

After completing a construction project, restoring the site to its original state is essential. This involves properly disposing of all waste and minimizing damage to the ecosystem. Such efforts protect local habitats and reduce lasting negative effects.

Eco-Friendly Practices and Certifications

Working with waste management companies that adopt eco-friendly methods can help achieve environmental certifications like BREEAM (Building Research Establishment Environmental Assessment Method). These companies handle and recycle waste effectively, enhancing project sustainability.

Efficient Waste Management

Choosing the right skip size improves waste management efficiency. Matching skip sizes to waste volumes reduces the number of lifts required, saving time, effort, and costs while lowering environmental impact.

Choosing the Right Crane Skip Bin

1. Volume and Type of Waste

To choose the right skip bin, assess the type and amount of waste your project produces:

– Muck Skips: Suitable for heavy materials like soil, rubble, or sand.

– General Construction Skips: Versatile for mixed waste across different projects.

2. Ease of Loading

Crane skip bins streamline material movement:

– Cut down on manual labor, saving time and effort.

– Ensure smooth operations on construction sites.

3. Local Council Permits

- Check if permits are needed to place a skip bin on public land.

- Follow council rules to avoid legal issues.

- For details, please refer to our previous blog

4. Site Suitability

Make sure the site meets these conditions:

– Space: Allow enough room for the crane and skip bin.

– Ground Stability: Ensure the surface can support the equipment.

– Accessibility: Position bins where the crane can easily reach.

5. Proper Attachment and Maintenance

- Secure bins with chains or lifting slings to prevent accidents.

- Regularly inspect equipment for wear and tear to ensure safety.

6. Weight Limits

- Verify the weight limits for both the skip bin and the crane.

- Standard skip bins typically handle 1–1.5 tonnes. Match this with crane capacity.

Safety and Compliance

Workplace Compliance

- Crane skip bins must meet strict safety regulations, including:

- Regular maintenance and inspections to ensure safety and proper function.

- Ensuring bins are not overloaded, and quickly addressing any safety concerns reported by drivers, workers, or customers.

- Drivers must inspect lifting points for wear or cracks and inform customers about acceptable fill levels.

- Employers must train employees handling bins, focusing on safe work practices and fault detection.

Material Standards

- Crane skip bins are made from reinforced steel to withstand heavy-duty construction environments.

- Compliance with Australian Standards, such as AS4991 (Lifting Devices) and AS1418.17 for crane man cages, is mandatory. This includes proof-load testing and design registration.

- Components like chains, hooks, and links are made from high-strength steel for safe handling of heavy loads.

Regular Inspection and Maintenance

- Inspecting lifting chains and slings regularly is crucial to maintaining load safety.

- Chains and parts must be checked for wear and replaced immediately if damaged.

Compliance Certificates and Tags

- Proof Load Certificates confirming compliance with Australian Standards are required to use crane skip bins on construction sites.

- Lifting equipment must be compliance-tagged by the manufacturer before use.

Consequences of Non-Compliance

- Failing to meet safety and material standards can result in:

- Legal and financial penalties, including fines and the removal of bins.

- Worksite delays, property damage, and harm to reputation.

- In severe cases, legal action and court appearances, leading to additional fines and business losses.

A leading accessories supplier in Australia

Aresbins is a prominent accessories supplier in Australia, known for its diverse range of products and commitment to quality. The company specializes in providing a variety of accessories, catering to different markets and customer needs.

Recent Comments